Page 50 - Campbell Fittings

P. 50

c

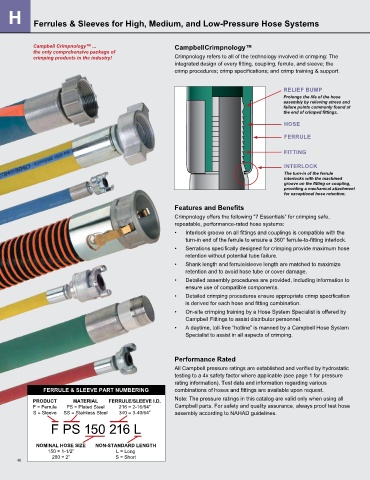

H Ferrules & Sleeves for High, Medium, and Low-Pressure Hose Systems

Campbell Crimpnology™ ... CampbellCrimpnology™

the only comprehensive package of

crimping products in the industry! Crimpnology refers to all of the technology involved in crimping: The

integrated design of every fitting, coupling, ferrule, and sleeve; the

crimp procedures; crimp specifications; and crimp training & support.

RELIEF BUMP

Prolongs the life of the hose

assembly by relieving stress and

failure points commonly found at

the end of crimped fittings.

HOSE

FERRULE

FITTING

INTERLOCK

The turn-in of the ferrule

interlocks with the machined

groove on the fitting or coupling,

providing a mechanical attachment

for exceptional hose retention.

Features and Benefits

Crimpnology offers the following “7 Essentials” for crimping safe,

repeatable, performance-rated hose systems:

• Interlock groove on all fittings and couplings is compatible with the

turn-in end of the ferrule to ensure a 360° ferrule-to-fitting interlock.

• Serrations specifically designed for crimping provide maximum hose

retention without potential tube failure.

• Shank length and ferrule/sleeve length are matched to maximize

retention and to avoid hose tube or cover damage.

• Detailed assembly procedures are provided, including information to

ensure use of compatible components.

• Detailed crimping procedures ensure appropriate crimp specification

is derived for each hose and fitting combination.

• On-site crimping training by a Hose System Specialist is offered by

Campbell Fittings to assist distributor personnel.

• A daytime, toll-free “hotline” is manned by a Campbell Hose System

Specialist to assist in all aspects of crimping.

Performance Rated

All Campbell pressure ratings are established and verified by hydrostatic

testing to a 4x safety factor where applicable (see page 1 for pressure

rating information). Test data and information regarding various

FERRULE & SLEEVE PART NUMBERING combinations of hoses and fittings are available upon request.

PRODUCT MATERIAL FERRULE/SLEEVE I.D. Note: The pressure ratings in this catalog are valid only when using all

F = Ferrule PS = Plated Steel 216 = 2-16/64” Campbell parts. For safety and quality assurance, always proof test hose

S = Sleeve SS = Stainless Steel 340 = 3-40/64” assembly according to NAHAD guidelines.

F PS 150 216 L

NOMINAL HOSE SIZE NON-STANDARD LENGTH

150 = 1-1/2” L = Long

200 = 2” S = Short

48